In truth, identical to with each different space of present grand prix equipment, groups are continuously searching for marginal achieve enhancements to assist make them winners.

Taken right down to its most simple ingredient, this implies making issues lighter, and stronger – and making certain that each half is completely match for goal.

Groups are additionally at all times in search of indicators of any revolutionary expertise that may assist shoot them away from their rivals.

Progress within the uncooked supplies that vehicles are constituted of just isn’t one thing that comes purely from inside the manufacturing facility partitions of F1’s rivals, although, as a result of they’re reliant on outdoors suppliers which have a a lot better understanding of the composite trade.

And none stands out extra on the present F1 grid than Belgian multinational science firm Solvay. It helps provide each F1 workforce on the grid, to a higher or lesser extent, with its carbonfibre merchandise, which go on to be in the end formed and become the automobile components we see out on monitor.

Ferrari F1-75 ground element

Picture by: Mark Sutton / Motorsport Pictures

Solvay has seen dramatic adjustments within the expertise and understanding of carbonfibre because it first appeared in F1 – as groups have continuously pushed issues to the restrict.

As Gerald Perrin, International Program Director of Automotive at Solvay, tells Autosport: “Up to now 20 years, each single automobile profitable the F1 championship was manufactured with Solvay supplies.

“Now we have been extraordinarily pivotal in working with the groups in enhancing the security of the vehicles. However the kind of supplies which are used right now are utterly completely different to what was designed within the ’80s.

“There’s optimisation of the fibre and the resin, and the way you mix and work together these two supplies.

“All the pieces has been utterly optimised, whereas within the ’80s it was most likely one match for all: it was lighter than steel so it was already tremendous good!”

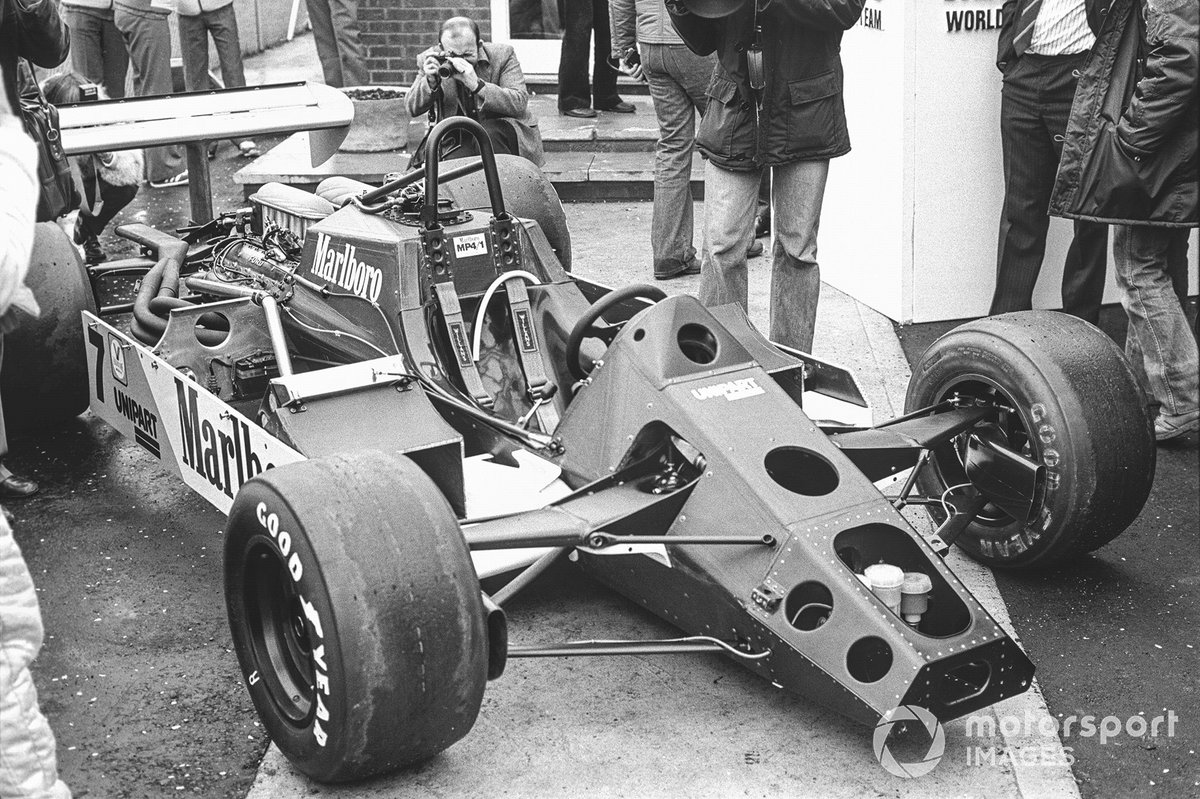

McLaren MP4/1

Picture by: Motorsport Pictures

Whereas many years in the past, a automobile might have used two or three several types of carbonfibre for various functions, now it’s a totally completely different ballgame with round 40 sorts all through.

Mark Steele, buyer engineering supervisor of automotive composites for Solvay, says: “Once I suppose again to the Eighties they used one or two, possibly even three, several types of epoxy resins to translate the efficiency into the fibre.

“These days, the vehicles do not use one or two resins, they use a number of resins. They’re very, very bespoke resins for very particular purposes: whether or not it is a suspension arm, which is pushed in the end by stiffness, via to a facet intrusion pod, which is designed to guard the driving force.

“In the event you go take a look at the collection of fibres which are on the market, I would not say there’s a whole bunch, however there’s huge selection there.

“You wish to choose a fibre for the kind of property you need, after which attempt to match that up with the chemistry behind the resin, as a result of you’ll be able to’t use all chemistry with all fibres. I believe that is the place the benefits have actually come from.

“The consistency has improved rather a lot too. That permits groups to actually stress their components to the final word restrict, figuring out that they’ll fail very constantly. Which means they’ll drag each final little bit of efficiency out of the half.”

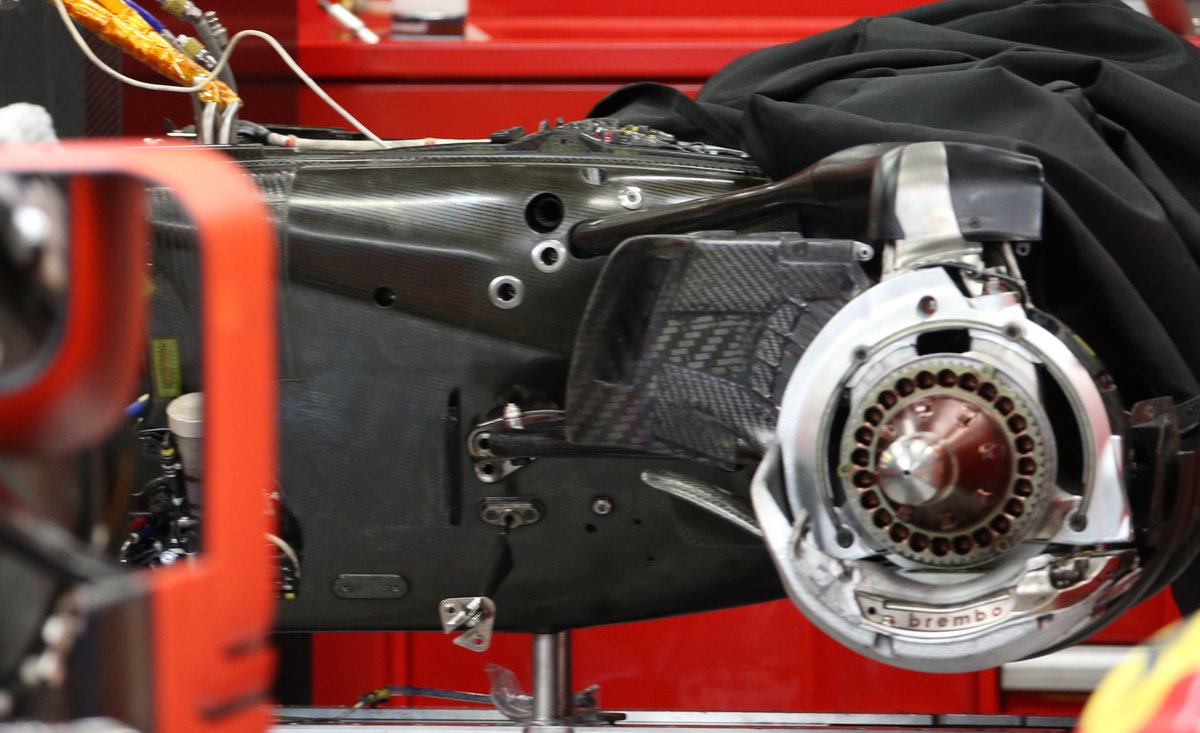

Ferrari SF16-H, carbon case on the gearbox

Picture by: Giorgio Piola

New guidelines challenges

Solvay has witnessed many rule adjustments through the years and has had to answer the rising calls for for more durable supplies to face up to ever-stricter crash checks.

However F1’s new guidelines period for 2022 has thrown up some particular challenges, as groups have discovered themselves battling to get right down to the load restrict.

Such was the desperation to trim off the additional kilograms, that some groups needed to assault their liveries to strip again any extra paint – leaving the naked carbonfibre uncovered. Steele explains that Solvay needed to play its half too in producing supplies that might assistance on this entrance.

“We developed a really particular product for a few of the bodywork on the automobile, the place they had been having to place simply micron ranges of paint on,” he mentioned. “So the floor end needed to be virtually perfection earlier than they paint it.

“Then, after they abrade into the paint, as a result of very often they must take away it or clear the automobile, we have needed to provide you with some some formulations, that are tremendous abrasion resistant.

“It means after they do abrade it, it does not minimize into the carbon. These are the actually small little particulars which permits them to drop weight.”

Lando Norris, McLaren MCL36

Picture by: Steven Tee / Motorsport Pictures

What comes subsequent?

F1 groups and corporations like Solvay are at all times seeking to the long run and the place enhancements will come from subsequent. However it’s essential to state that finish targets are altering for all rivals.

The place as soon as they could solely have been all in favour of efficiency, now groups are having to juggle a bunch of competing elements.

There’s the price cap subject, which implies good worth for cash is important. However sustainability can also be turning into important and that’s one thing that counts for what supplies vehicles use too.

Steele provides: “It is very troublesome to foretell how they’ll transfer however, from a fabric standpoint, right now they’re utilizing essentially the most unique fibres, they usually’re utilizing unique resins.

“However the one factor that’s enjoying an element is the finances cap for the groups. It impacts the larger groups greater than others as a result of they are going to actually have much less cash to spend on a few of these actually highly-exotic merchandise.

“In order that’s most likely the largest factor: making an attempt to make supplies more economical while making an attempt to take care of efficiency.

“There are additionally conversations round the usage of bio sustainable uncooked [materials], as a result of the rules would possibly drive groups to begin taking a look at having much less petroleum-based sort supplies within the automobile.

“It’s these types of rules which can transfer the F1 market in a sure course.”

Autoclave

Picture by: Franco Nugnes

However this isn’t to say that, in the long run, groups will flip their again on progress that does provide lap time enchancment. Perrin sees two avenues of intense improvement over the following few years.

“Solvay is enjoying with additive manufacturing,” he explains. “Like 3D printing, additive manufacturing is one thing that we’re already fairly current and superior in.

“It’s a completely different strategy to make an element, and that is one thing we see that’s interesting for F1 and for a number of markets.

“Then I’d say outdoors of composites, we’re a large participant for electrification. We’re enjoying rather a lot on battery expertise and even boosting the electrical engine efficiency.”

Solvay sees scope for higher use of carbonfibre components in electrical motors. These can contribute to much less inertia and better rotational speeds of inner parts to permit them to spin up and decelerate a lot quicker.

However there are hints too of revolutions to return in general battery expertise, which might be pivotal when F1 strikes to its new engine guidelines period from 2026.

Perrin provides: “We additionally engaged on the chemistry of the battery itself. Right this moment most individuals are utilizing I’d say standard batteries, however there’s new expertise on batteries that we are able to foresee in 2025.

“This can utterly change issues when it comes to power density, so the capability of the battery, and in addition the worldwide weight that you’ll want to carry for a similar quantity of power, will drastically be lowered.

“It is not prepared but, however that is one thing that we see approaching the horizon.”

Carbonfibre helped open a brand new period for F1 again within the Eighties. It seems set to play a key half in shaping its long-term future too.