Germany is broadly acknowledged because the world chief in plastics recycling, so it is going to come as no shock that recycling is a outstanding theme at subsequent month’s Ok 2022 present in Düsseldorf.

After all recycling can be a significant world concern, and the Ok Present is a world showcase of recent know-how. Governments and firms are setting bold targets for plastic merchandise and packaging recycling charges, which would require extra and higher recycling tools to fulfill the required throughput. Many exhibitors serving recyclers see this problem as a possibility. Suppliers plan to reveal how their newest tools handles extra supplies, is extra environment friendly and produces greater high quality output than ever achieved earlier than.

All steps within the recycling chain will likely be on show. For these strolling the mammoth present, it provides as much as a tour of assorted recycling loops, from collected waste to new manufactured merchandise. Guests will see the persevering with evolution of business recycling, as processes are mixed, streamlined, and up to date with new applied sciences.

Recyclate Preparation

Subsequent Technology Recycling will supply a dwell demonstration of its Nxt:Gran system, which contains a number of steps—shredding, feeding and extruding—right into a single operation. Total output has been elevated by bettering the chopping effectivity of the shredder and optimizing materials feeding. Subsequent Technology may even spotlight its P:React machine, which makes use of liquid-state polycondensation to take away contaminants from PET, permitting manufacturing of 100% food-grade rPET.

The NXT:Gran system incorporates shredding, feeding, and extruding. (Photograph: Subsequent Technology Recycling)

Saperatec will likely be highlighting its not too long ago introduced hot-wash separation know-how for composite multilayer packaging. The method provides no contaminants to recycled polymers, and all chemical compounds used within the course of adjust to EU food-contact laws, serving to to make sure the outputs are appropriate to switch virgin uncooked supplies in movie and foil-based packaging.

Improvements will likely be exhibited in each step of the method chain, from grinding, washing, drying, compounding and repelletizing to injection molding.

Lindner will likely be presenting the upgraded Jupiter BW shredder for the primary time. Its newly developed cutter system produces a homogenous particle measurement with fewer fines and in addition optimizes particle measurement for near-infrared (NIR) sorting.

Lindner may even exhibit improvements in washing and drying. Its Rafter prewash system consists of a bigger rotor that lengthens dwell occasions. Ecodry is a brand new thermal dryer boasting vitality financial savings of as much as 30%, achieved by strategic use of warmth exchangers and insulation.

Hosokawa Alpine will current its new Polyplex PPC 50/120 Combi Grinder. The rotor is organized vertically, with an higher shredding zone and a granulator zone under. The joint drive reportedly makes measurement discount extra vitality environment friendly. The agency may even current the Polymer-Line PL-XS 45/100, a compact granulator for economical measurement discount of cumbersome plastics.

Herbold Meckesheim could have its HV sequence Plastcompactor, which is used for agglomeration of recovered supplies, in addition to drying, recrystallization and compounding. Pre-granulated materials is screw-fed into the processing space, between a set disk and a rotating disk, the place it’s quickly heated by friction. Each disks are outfitted with replaceable kneading rails.

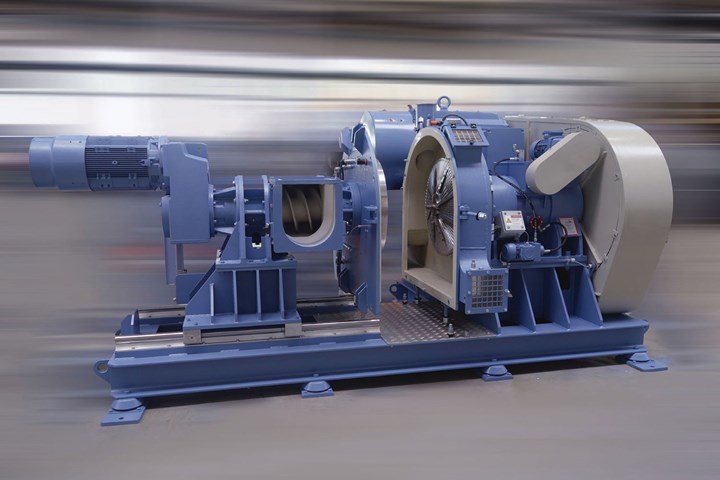

The HV Plastcompactor for agglomeration, drying, recrystallization, and compounding. (Photograph: Herbold)

Herbold may even show the SML 60/100 Sb, a granulator for PET bottles. Materials is fed by three vertical screws, a novel setup that reportedly gives constant feed charges, lowered energy consumption, no materials flyback, quieter operation, lowered put on on the chopping chamber, and lowered fines and dirt compared with gravity feed.

Herbold’s 216 T Sequence is an intensive washer that will also be used as a dryer. For laundry flakes, it contains a particular high-speed rotating agitator, a stainless-steel display basket, and double outboard bearings.

Sorema will likely be highlighting its recycling course of for PET bottles, which transforms collected client waste into clear, dried PET flakes. The washing course of water strikes in the other way of fabric movement, such that the ultimate rinse is accomplished by the cleanest water, which is then reused in upstream cleansing phases. Capacities vary from 1320 to twenty,000 lb/hr (600 to 9000 kg/hr).

Recycling in Extrusion, Compounding, Molding

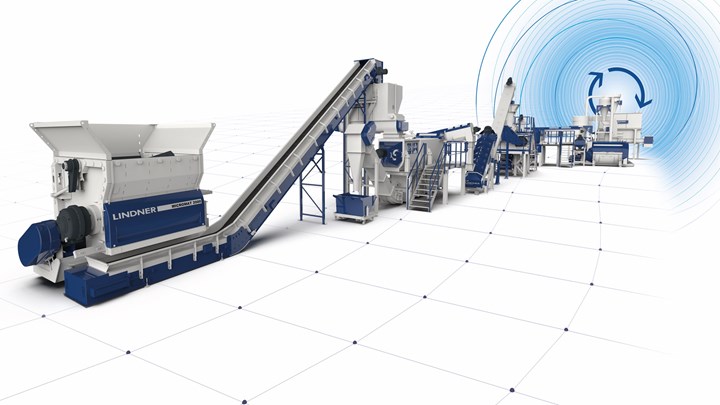

The open-air fairground at Ok Present will likely be devoted to a Round Financial system Discussion board, permitting dwell demonstrations of product recycling. For instance of a complete washing plant, Lindner will current a shredding, washing and drying unit with built-in water therapy and can reveal recycling dwell a number of occasions every day. Inflexible plastics will cross by the Micromat HP shredding machine, a brand new sequence that includes bolted knives and an enhanced drive, which might deal with both movie or inflexible plastics. The demonstration will proceed with the clear and homogeneous flakes being instantly molded into new product, with out want for extrusion.

Lindner’s built-in recycling system with shredding, washing, and drying.

(Photograph: Lindner)

Recycling will likely be a theme in injection molding as properly. Arburg will reveal manufacturing of plastic plugs from recyclate on its electrical Allrounder 370 A injection molding system with Multilift robotic. At Arburg’s predominant sales space, different injection machines may even reveal the capabilities of its recyclate processing bundle. An Allrounder 470 A will mildew PP handles from PCR; an Allrounder 270 S will produce tweezers from glass-reinforced PPS recyclate; and an Allrounder 375 V will produce a bicycle software from recycled nylon.

Arburg Allrounder 370 A will likely be producing plastic plugs (inset) from recyclate.

(Photograph: Arburg)

Erema will spotlight its new, bigger and extra environment friendly Vacurema recycling extruder, which guarantees a broader processing window and gentler materials therapy. It has a capability of 13,200 lb/hr and makes use of 10% much less vitality than earlier tools. Erema’s newest extrusion filter, the Laserfilter 406 options 50% extra filtering space and elevated throughput.

Erema may even current its knowledge options for course of monitoring and tools upkeep. PredictOn is its system of software program and instrumentation for early detection of important element failure, and Bluport is a set of apps for machine efficiency monitoring. (Extra particulars in final month’s Holding Up part.)

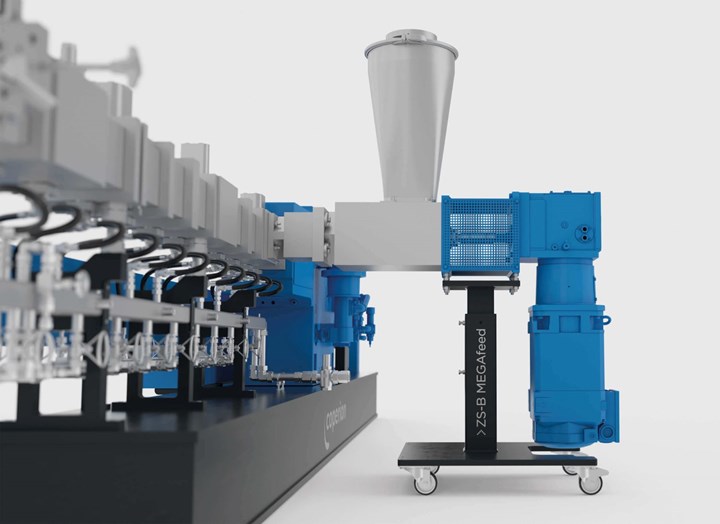

Coperion’s ZSB Megafeed facet system permits feeding of low-density recyclate.

(Photograph: Coperion)

Coperion will likely be exhibiting a complete manufacturing line for PET recycling. The exhibit will embody bulk solids dealing with, feeding, extruding and pelletizing. On the heart will likely be a system constructed round a ZSK 58 MC18 twin -screw extruder, configured for manufacturing high-quality PET utilizing recycled supplies, with out the need for predrying and crystallization. The extruder will likely be fed by the SWB-300 belt feeders, an S100 single-screw pre-feeder, and a brand new ZSB 70 Megafeed facet feeder, which can reliably feed giant portions of plastic recyclate with densities as little as 12.5 lb/ft3. After melting, devolatilization, and homogenization within the extruder, the fabric stream is filtered and transferred to an underwater pelletizer. The pellets are then condensed in a strong state polycondensation response, then are able to be reprocessed into bottles, fibers, or movies. The output of this course of has been accredited by the FDA for direct meals contact (letter of non-objection).

KraussMaffei will reveal compounding of three completely different supplies in its direct-compounding injection molding (DCIM) course of: PP fiber from face masks, shredded HDPE from packaging, and HDPE blow molding scraps from toy manufacturing. The mix of molding and compounding in a single heating course of reduces materials price by as much as 50%. DCIM makes use of a single-screw extruder on the injection machine, which is extra economical than KM’s IMC course of utilizing a twin-screw compounder on the injection press. On the Ok present the direct compounding course of will likely be used to make collapsible crates for transporting contemporary fish.

Collapsible crate constructed from direct-compounding injection molding of recycled PP or HDPE.

(Photograph: KraussMaffei)

Aisa Automation of Switzerland will current the IPRA 250 recycling plant, which processes blended, multi-component plastics into new, easy recycled merchandise with none chemical separation, washing, or granulation.

Chemical Recycling

A number of exhibitors will likely be presenting options for brand spanking new instructions within the space of chemical recycling, typically referred to as superior recycling, with the potential to course of plastic waste into monomer feedstock. Coperion will spotlight tools capabilities that assist chemical recycling of blended waste, particularly packaging waste, which embody the Ok-Tron feeder for correct loading of uncooked supplies and the ZSK twin-screw extruder for getting ready materials for chemical recycling reactors.

Erema will likely be presenting its entry into chemical recycling, Chemerema. Its extrusion course of is particularly tuned for downstream enter to chemical recycling processes.

Learn: Liquid Composites Molding Progresses at BMW and VW

California startup Novoloop will current its Oistre product, a PU constructed from recycled PE. Novoloop says its course of is an easier, cheaper and lower-carbon various to pyrolysis.

Rittec of Germany will current its revolPET know-how for breaking down PET from blended plastic waste to monomer materials. Rittec has now tailored this know-how to polyester materials, opening up the potential for recycling textiles.